Pickling bath

After pickling and ample rinsing with water (high pressure with a low chloride content, preferably below 50 ppm) the corrosion resistance is restored in the welded area.

TACAB NOXfree pickling bath

The pickling baths used today are almost always hazardous to health and emit dangerous gases and the use demands very strict directives for ventilation, protective equipment etc. TACAB noxfree pickling bath is patented, environmentally suited pickling bath that drastically reduces the hazardous at use. No toxic and environmentally harmful gases are given of during pickling process.

The useful life of the noxfree pickling bath is much longer than for a conventional nitric acid – hydrofluoric acid bath.

TACAB noxfree pickling bath is sold in the following sizes of packages: 25, 200 and 1000 litres.

For larger volumes ask for quotation.

TACAB Pickling Bath Standard Concentrated

TACAB pickling bath concentrated is sold in the following sizes of packages: 25, 200 and 1000 litres.

For larger volumes ask for quotation.

How to prepare TACAB pickling bath concentrated:

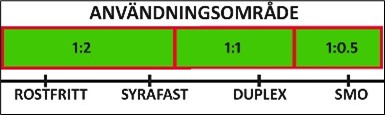

resistant steel grades.

Mix ratio 1:2 (1 part concentrated pickling bath + 2 parts of water).

Higher alloyed steel grades (example: duplex).

Mix ratio 1:1 (1 part concentrated pickling bath + 1 part of water).

Very high alloyed steel grades (example: super duplex).

Mix ratio 1:0.5 (1 part concentrated pickling bath + 0.5 parts of water).

Use only fresh water (drinking waster quality with low cloride content preferably below 50 ppm).